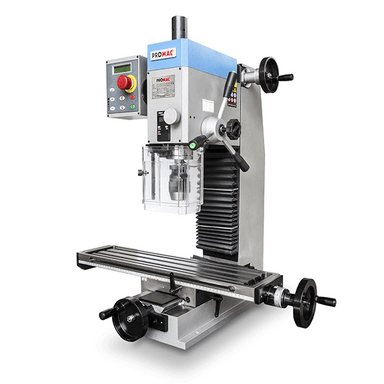

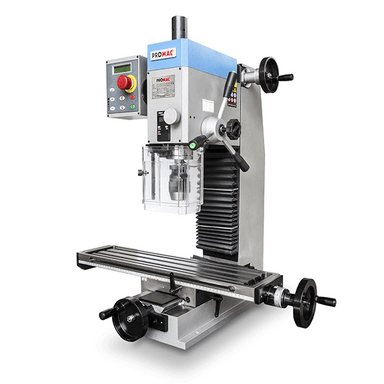

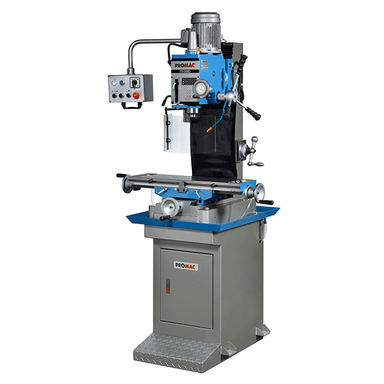

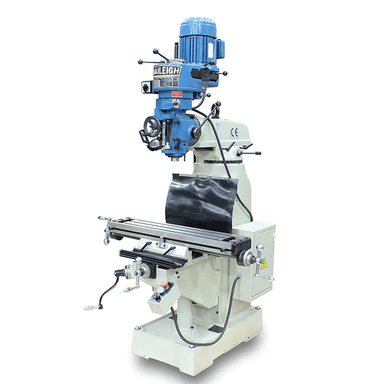

Promac PBM-1839BDV Vertical Mill Drill

Unleash Precision with Promac PBM-1839BDV Vertical Mill Drill Promac PBM-1839BDV Vertical Mill Drill Overview Enter the era of meticulous drill...

View full detailsWelcome to the milling machine haven for all precision enthusiasts! Whether you're a seasoned engineer, a budding model maker, or a workshop looking to expand its capabilities, we offer a diverse collection of milling machines to tackle your most demanding projects.

A milling machine is a powerhouse tool that utilizes rotating cutting tools to remove material from a workpiece. Unlike lathes that focus on shaping along a central axis, milling machines offer multi-axis machining capabilities, allowing for intricate three-dimensional creations. They excel at tasks like:

Milling machines are essential for various applications in metalworking, but their versatility extends to plastics, wood, and even composites.

Spindle: The heart of a milling machine, the spindle is a rotating shaft that holds the cutting tool. It spins at high speeds, removing material from the workpiece.

Axes of Movement: Unlike lathes that primarily focus on a single axis of rotation, milling machines offer multi-axis machining capabilities. This allows for the creation of intricate three-dimensional features. The most common milling machines have 3 axes (X, Y, and Z), allowing for movement in all three directions. More advanced machines can have up to 5 axes for even greater flexibility.

Cutting Tools: Milling machines utilize a wide variety of cutting tools depending on the material being machined and the desired outcome. These tools come in different shapes and sizes, including end mills, ball nose cutters, face mills, and many more.

Worktable: The worktable is the platform that securely holds the workpiece during the machining process. It can move along the X and Y axes to position the material precisely for the cutting tool. Some milling machines also have a rotary table attachment that allows for work at various angles.

Manual vs. CNC Control: Milling machines come in two main control options: manual and CNC (Computer Numerical Control). Manually controlled machines require the operator to move the cutting tool and workpiece throughout the machining process. CNC milling machines, on the other hand, are programmed to execute precise movements automatically, offering greater precision, repeatability, and the ability to create complex designs.

At Tool Bay Direct, we understand that every project demands the right tools. That's why we offer a variety of milling machines to cater to diverse needs:

These user-friendly machines feature a vertically moving spindle, perfect for precise milling and drilling operations. Ideal for workshops and hobbyists venturing into the world of CNC machining.

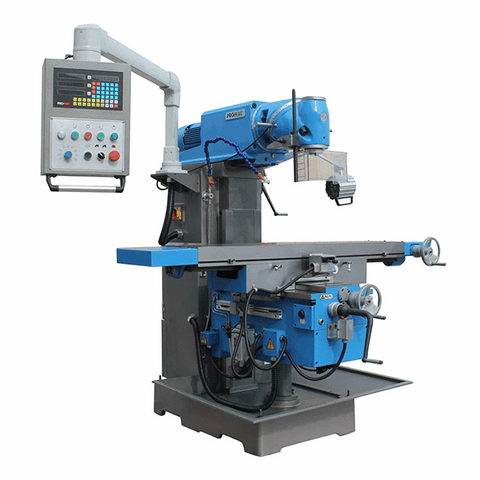

A classic design offering a horizontal spindle for a wider range of milling operations. Popular with toolmakers and machinists for their versatility and affordability.

For ultimate precision and repeatability, explore our CNC (Computer Numerical Control) milling machines. Programmable for complex designs and high-volume production, these state-of-the-art machines are ideal for professional workshops.

Selecting the perfect milling machine depends on several factors:

Have questions or need assistance in choosing the right Milling Machine for your needs? Our team of experts is here to help!

Phone:

Both milling machines and lathes are used for shaping materials, but they excel in different ways. Lathes primarily focus on shaping a workpiece along a central axis, making them ideal for cylindrical or spherical objects.

Milling machines, on the other hand, offer multi-axis machining, allowing for intricate three-dimensional features like flat surfaces, pockets, and complex contours.

Milling machines are incredibly versatile and can handle a wide range of materials! They're most commonly used for metals, but they can also work with plastics, wood, and even composites. The specific type of material will influence the choice of cutting tool and machining parameters.

There are two main control options for milling machines: manual and CNC. Manual machines require more operator skill and experience to achieve precise results. CNC milling machines, however, are programmed for automated operation, making them ideal for beginners or projects demanding high repeatability.

The perfect milling machine depends on your specific needs. Consider the materials you'll be working with, the size and complexity of your projects, and the level of precision required. Additionally, think about your workshop space and budget.

Manual machines might be sufficient for simpler tasks, while CNC offers automation for intricate designs or high-volume production.

Safety is paramount when operating a milling machine. Always wear appropriate eye protection, gloves, and respirator to protect yourself from flying debris and dust. Secure the workpiece firmly to the worktable, and ensure you understand the operation of the machine before starting.

Never reach into the machine while it's running, and power down the machine before making adjustments or changing tools.

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Unleash Precision with Promac PBM-1839BDV Vertical Mill Drill Promac PBM-1839BDV Vertical Mill Drill Overview Enter the era of meticulous drill...

View full details Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

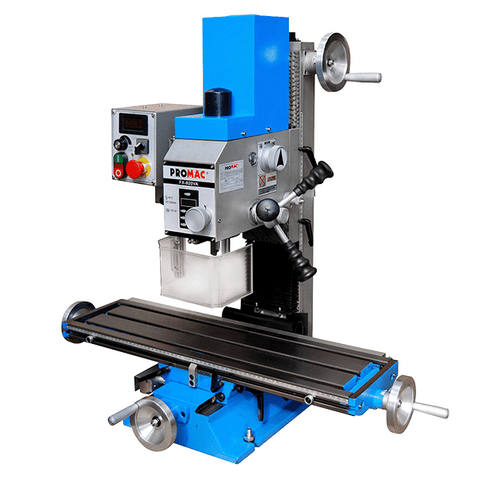

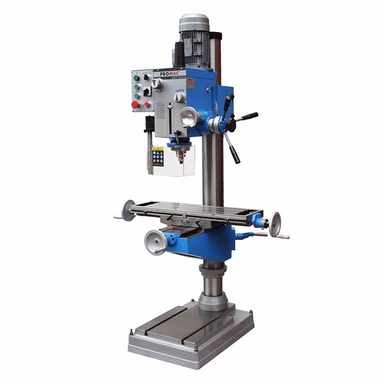

Enhance Your Workshop with Promac JMDT_764016 Vertical Mill Drill Tapping: Precision in Vertical Milling and Drilling Promac JMDT_764016 Vertica...

View full details Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Promac JMDT_763016 Vertical Mill Drill Tapping: Precision and Versatility Combined Promac JMDT_763016 Overview Experience unparalleled precisio...

View full details Save Liquid error (snippets/product-badge line 32): Computation results in 'NaN' (Not a Number)%

Save Liquid error (snippets/product-badge line 32): Computation results in 'NaN' (Not a Number)%

Empowering Precision and Versatility with the Promac JMDT-804516-DRO Vertical Mill Drill Promac JMDT-804516-DRO Vertical Mill Drill Overview Un...

View full details Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Efficiency and Precision: The Promac JMD_45PFD-T Vertical Mill Drill Promac JMD_45PFD-T Vertical Mill Drill Overview Enhance your machining cap...

View full details Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

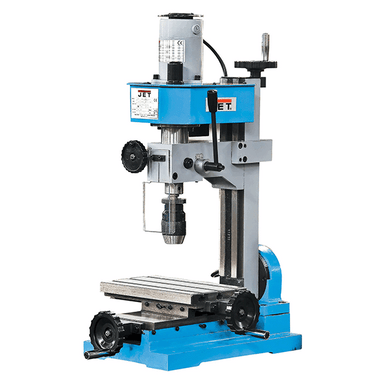

Promac JMD_3-M Vertical Mill Drill: Precision and Versatility Combined Promac JMD_3-M Vertical Mill Drill Overview Step into the realm of high ...

View full details Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Enhancing Precision and Versatility with Promac JMD_1-M Vertical Mill Drill Promac JMD_1-M Vertical Mill Drill Overview Unlock new levels of pr...

View full details Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

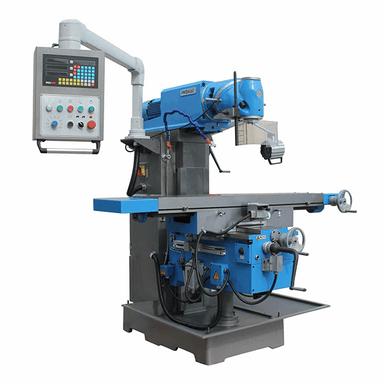

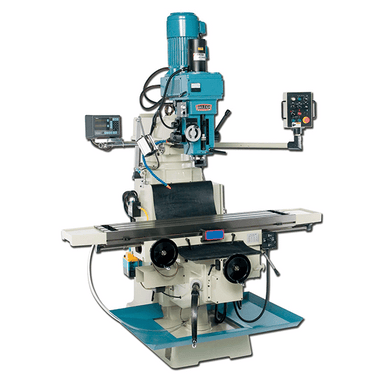

Experience Precision and Versatility: Promac JM_125-DRO Vertical Mill Delivers HURON Type Milling Head with 360° Tilt, Automatic Feeds, and More! ...

View full details Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Discover Precision and Versatility with Promac FX_820VA Vertical Mill Drill Promac FX_820VA Vertical Mill Drill Overview The Promac FX_820VA Ve...

View full details Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Unlock Precision and Versatility with Promac FX_388D Vertical Mill Drill Promac FX_388D Vertical Mill Drill Overview Step into the realm of hig...

View full details Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

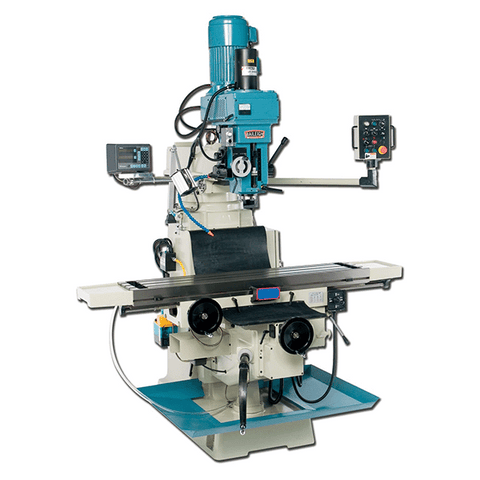

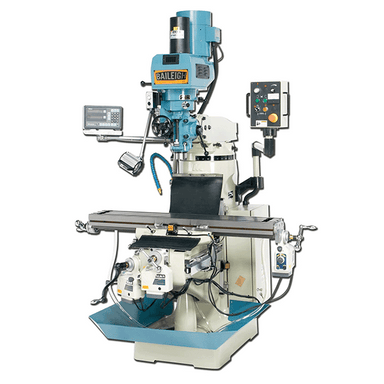

Enhancing Precision and Efficiency with Baileigh Vertical Mill VM-949 Baileigh Vertical Mill VM-949 Overview Step up your milling game with the...

View full details Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

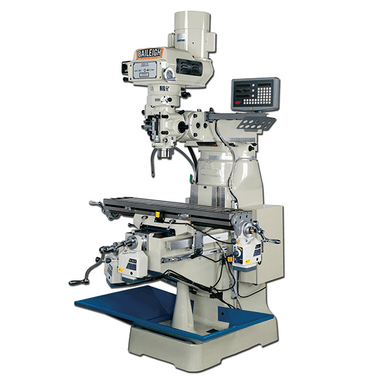

Maximizing Precision and Efficiency with the Baileigh Vertical Mill VM-942-1 Baileigh Vertical Mill VM-942-1 Overview Discover the Baileigh Ver...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

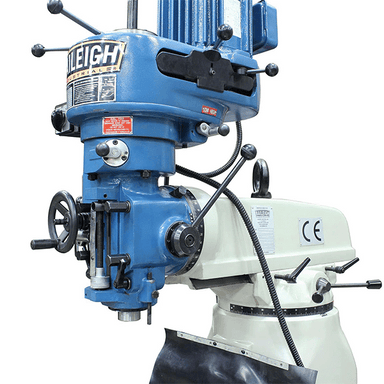

Unlock Precision and Power with the Baileigh Vertical Mill VM-836E Baileigh Vertical Mill VM-836E Overview Introducing the Baileigh VM-836E Ver...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

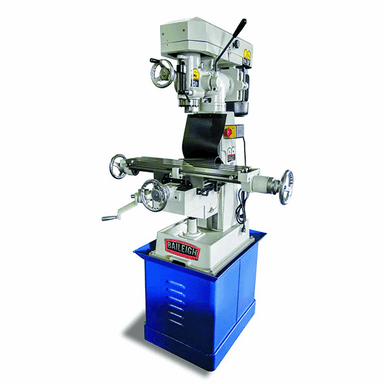

Transform Your Workshop Efficiency: The Baileigh Vertical Mill VM-626-1 Offers Precision Milling for Every Craftsman Baileigh Vertical Mill VM-6...

View full details Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

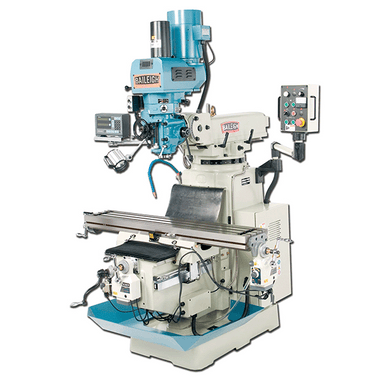

Elevate Your Machining to the Next Level: The Baileigh Vertical Mill VM-1258-3 Delivers Unmatched Precision and Reliability Baileigh Vertical Mi...

View full details Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Elevate Your Milling Projects: The Baileigh VM-1054-3 Vertical Mill Delivers Unrivaled Precision and Performance Baileigh Vertical Mill VM-1054-...

View full details