DIMAKIN Bandsaw BS-270-SM

Experience Unmatched Versatility and Reliability with the DIMAKIN Bandsaw BS-270-SM, Your Go-To Tool for Precision Metal Cutting in Any Workshop ...

View full detailsAre you a metal fabrication professional or a serious DIY enthusiast looking for precision cutting tools? Look no further than our curated selection of high-quality band saws and cold saws. Whether you're dealing with thick steel plates, delicate pipes, or intricate metal shapes, we have the perfect saw to deliver clean, accurate cuts every time.

Cutting Capacity

Both band saws and cold saws boast impressive cutting capacities, allowing you to tackle a range of material thicknesses and widths. Band saws often offer more versatility, handling thicker materials and a wider variety of shapes due to the continuous blade. Cold saws prioritize precision cutting of solid bars and profiles.

Cutting Precision

Clean and accurate cuts are essential for any metalworking project. Both saws deliver exceptional precision, with band saws offering a slight edge for intricate cuts due to the continuous blade's flexibility. Cold saws excel in repetitive, straight cuts with their high-speed, rigid blades.

Material Versatility

Band saws are true workhorses, capable of cutting a wide range of metals, including ferrous and non-ferrous materials, tubing, and even delicate shapes. Cold saws primarily focus on solid metals like steel and aluminium, making them ideal for fabrication shops dealing with consistent material types.

Blade Options

Both saws utilize specialized blades for optimal performance. Band saws offer a vast selection of blade sizes and tooth configurations to match the specific material and desired cut (straight, curved, angled). Cold saws typically have a more limited blade variety, focusing on high-speed blades designed for straight cuts in solid metals.

Both band saws and cold saws are metal cutting machines, but they have some key distinctions:

These versatile saws utilize a continuous, looped band blade to make continuous cuts. They excel at handling a wide variety of materials and shapes, from straight cuts to curves. Band saws are known for their clean cuts and minimal material wastage.

Cold saws employ a circular blade that spins at high speeds to make straight cuts. They're ideal for repetitive cutting of solid bars, tubes, and profiles. Cold saws prioritize speed and precision for production environments.

Our extensive collection offers a variety of band saws and cold saws to suit your specific requirements. Here's a quick guide to help you choose:

Have questions or need assistance in choosing the right Band Saws or Cold Saws for your needs? Our team of experts is here to help!

Phone: 03301 338004

Email: info@toolbaydirect.co.uk

It depends on your cutting priorities! Band saws are more versatile, tackling various materials, thicknesses, and even curved cuts. Cold saws excel at high-speed, precise straight cuts in solid metal for production environments.

Safety first! Always wear safety glasses, gloves, and proper clothing. Secure your material firmly in the saw's vice. Ensure the blade guard is in place and functioning correctly. Turn off and unplug the saw before making blade adjustments.

Consider the material you're cutting and the desired cut type. Band saw blades come in various sizes and tooth configurations – for straight cuts, choose blades with fewer teeth; for intricate cuts, opt for finer teeth. Cold saw blades prioritize high-speed cutting of solid metals. Consult your saw's manual or a specialist for specific blade recommendations.

Dull blades compromise cut quality and safety. Replace your band saw blade when teeth become worn or chipped. Cold saw blades can often be resharpened, extending their lifespan. Regularly inspect both blades for signs of wear and tear.

Several factors can contribute to this. Ensure the blade is properly tensioned and aligned with the saw guides. Check if the material is securely clamped to prevent movement during cutting. A worn-out blade can also cause a loss of straightness. Consider replacing the blade if other solutions don't resolve the issue.

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Experience Unmatched Versatility and Reliability with the DIMAKIN Bandsaw BS-270-SM, Your Go-To Tool for Precision Metal Cutting in Any Workshop ...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Enhance Your Cutting Capabilities with the SIP 8" Swivel Metal Cutting Bandsaw (1 Phase): Engineered for Precision and Durability in Professional S...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Experience Unparalleled Cutting Precision with the SIP 18" Metal Cutting Bandsaw (3 Phase), Your Industrial Solution for Metalworking Excellence ...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Experience Unmatched Precision with the SIP 18" Metal Cutting Bandsaw (1 Phase) 230v, the Ultimate Tool for Professional Metalworking and Heavy-Dut...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Master Your Woodworking Art: The SIP 16" Professional Wood Bandsaw - Precision and Power for Complex Projects SIP 16" Professional Wood Bandsaw ...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Maximize Your Metalworking Potential with the SIP 15" Swivel Pull Down & Auto-Cut Metal Cutting Bandsaw: Precision and Power in Every Cut SI...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

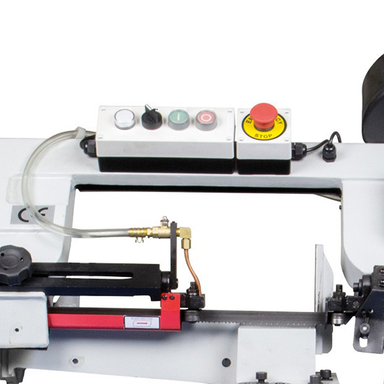

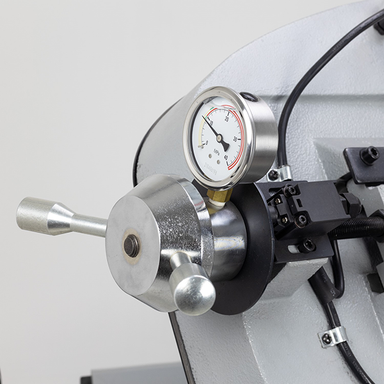

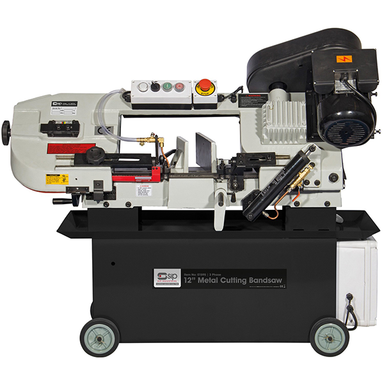

Streamline Your Metal Cutting with SIP 12” Gear Drive Metal Cutting Bandsaw: Precision, Efficiency, and Reliability for Industrial Applications ...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

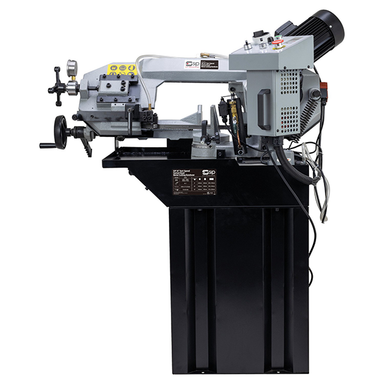

Experience Unmatched Precision with the SIP 12" Metal Cutting Bandsaw (3 phase): The Ultimate Solution for Professional Metalworking Demands SIP...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Experience Advanced Metal Cutting with the SIP 10" VariSpeed Swivel Head Metal Bandsaw: Precision, Power, and Versatility for Professional Workshop...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Transform Your Metalworking with the SIP 8" Swivel Head Pull-Down MCB (230v): A Compact Powerhouse for Precision Cuts and Versatility SIP 8" Swi...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Transform Your Cutting Tasks with the SIP 10" Swivel Head Pull Down MCB (230v): A Fusion of Power, Precision, and Versatility for Professional Need...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Master Cutting Precision with Elmag MACC Special 411M/S Metal Bandsaw: Unleash Unmatched Quality and Performance in Metalworking Elmag MACC Spec...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Experience Cutting Excellence with Elmag MACC Special 411 CSO Metal Bandsaw: Your Partner in Precision and Reliability Elmag MACC Special 411 CS...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Streamline Your Cutting Operations with Elmag MACC Special 335 CSO Metal Bandsaw: Precision and Power at Your Fingertips Elmag MACC Special 335 ...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Refine Your Metalworking with Elmag MACC Special 330 M/S Metal Bandsaw: Precision Engineered for Optimal Performance Elmag MACC Special 330 M/S ...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Enhance Your Metal Fabrication with Elmag HY 230 Vario Metal Bandsaw: A Synthesis of Precision, Power, and Versatility Elmag HY 230 Vario Metal ...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Elmag HY 180-4 Metal Bandsaw: Your Solution for Precise and Versatile Metal Cutting Elmag HY 180-4 Metal Bandsaw Overview The Elmag HY 180-4 Me...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Elmag CY260-2G Mitre Bandsaw: Engineered for Precision and Versatility in Metal Cutting Elmag CY260-2G Mitre Bandsaw Overview The Elmag CY260-2...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Experience Precision and Flexibility with Elmag CY210-2GN Vario Mitre Bandsaw: The Metalworking Maestro Elmag CY210-2GN Vario Mitre Bandsaw Over...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Maximize Efficiency with Elmag CY210-2GN Vario Metal Bandsaw: Precision Meets Power in Metalworking Elmag CY210-2GN Vario Metal Bandsaw Overview...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Experience Cutting-Edge Efficiency with the DIMAKIN Coldsaw CS-350-DM, a Powerful Tool for Enhanced Metal Fabrication DIMAKIN CS-350-DM Coldsaw ...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Enhance Your Metalworking with the DIMAKIN Coldsaw CS-315-DM: The Ultimate Combination of Power and Precision DIMAKIN Coldsaw CS-315-DM Overview...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Experience Precision and Efficiency with the DIMAKIN Coldsaw CS-275-DM: Engineered for Enhanced Performance in Metal Fabrication DIMAKIN Coldsaw...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Enhance Your Workshop's Capability with DIMAKIN Bandsaw BS-420-DM: The Ideal Tool for Precision and Volume Overview of DIMAKIN Bandsaw BS-420-DM...

View full details