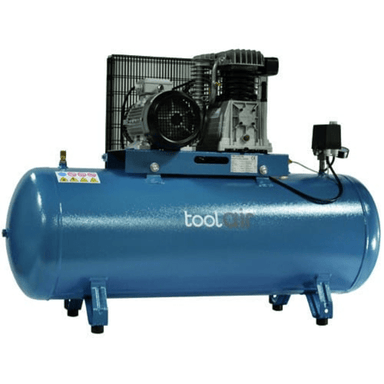

Toolair C_200-515 200lt Compressor 400v

Boost Your Productivity with the Toolair C_200-515: Engineered for High Performance in Transport, Workshops, and Agriculture. Toolair C_200-515 ...

View full detailsWelcome to your one-stop shop for air power! Whether you're a DIY enthusiast tackling weekend projects, a professional contractor, or a passionate automotive hobbyist, we offer a diverse range of air compressors to fulfill your needs.

Experience the efficiency and convenience of air compressors for a multitude of applications. From inflating tyres to powering pneumatic tools, our collection offers a variety of options to suit your requirements. Explore our selection and discover the perfect air compressor for your workshop, garage, or home.

An air compressor is a versatile tool that uses electricity or gasoline to compress air into a tank. This compressed air can then be used to power various pneumatic tools and equipment. Some common applications include:

Power Source

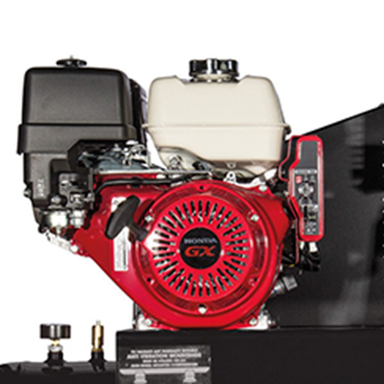

Air compressors come in two main power source options: electric and gas-powered. Electric compressors are quieter and more suitable for workshops or home use with access to outlets. Gas-powered compressors offer portability, making them ideal for on-site jobs where electricity might not be readily available.

Tank Size

The size of the tank is crucial as it determines the amount of compressed air available and the duration of continuous use before needing to refill. Larger tanks are better suited for applications requiring sustained air delivery, like powering sanders for extended periods.

Air Pressure (PSI)

Measured in Pounds per Square Inch (PSI), air pressure indicates the force behind the compressed air. Higher PSI is needed for demanding tasks that require more power, such as operating impact wrenches for lug nut removal.

Airflow (CFM)

Cubic Feet per Minute (CFM) represents the volume of air an air compressor can deliver in a minute. Applications requiring continuous airflow, like spray painting or powering sanders, benefit from higher CFM ratings.

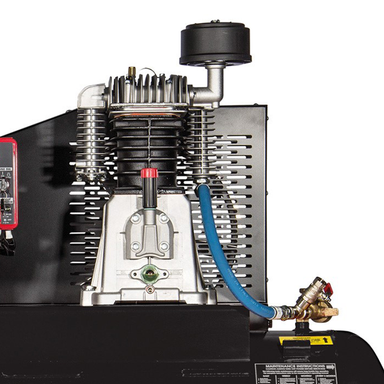

Lubrication

Air compressors come in two lubrication options: oil-free and oil-lubricated. Oil-free compressors are low maintenance and user-friendly, making them ideal for home use. Oil-lubricated compressors offer greater power and durability, handling heavy-duty tasks efficiently but requiring oil changes for maintenance.

Experience the efficiency and convenience of air compressors for a multitude of applications. From inflating tyres to powering pneumatic tools, our collection offers a range of options to suit your needs. Dive into our selection and find the perfect air compressor for your workshop, garage, or home.

Portable Air Compressors

Ideal for on-the-go tasks, our portable air compressors are compact yet powerful. Whether you're inflating sports equipment or tackling light-duty tasks, these portable units offer the flexibility you need. With easy-to-carry designs and reliable performance, they're perfect for DIY enthusiasts and professionals alike.

Industrial Air Compressors

For heavy-duty applications, explore our industrial air compressors. Built to withstand rigorous use in workshops and manufacturing environments, these units deliver consistent performance and reliability. With various horsepower options and tank capacities available, you can find the perfect solution for your business needs.

Oil-Free Air Compressors

Eliminate the hassle of oil maintenance with our oil-free air compressors. Perfect for applications where oil contamination is a concern, these units provide clean, dry air for precision tasks. From painting to dental work, you can trust our oil-free compressors to deliver exceptional results every time.

Silent Air Compressors

Reduce noise pollution in your workspace with our silent air compressors. Designed with advanced sound-dampening technology, these units operate quietly without sacrificing performance. Whether you're working in a shared environment or simply prefer a quieter workspace, our silent compressors offer the perfect solution.

With so many air compressors available, selecting the perfect one depends on your specific needs. Here are some key factors to consider:

Have questions or need assistance in choosing the right Air Compressor for your needs? Our team of experts is here to help!

Phone:

The choice between an oil-free and oil-lubricated air compressor depends on your usage and priorities. Oil-free compressors are:

However, oil-lubricated compressors offer:

If you need an air compressor for occasional DIY projects or light tasks, an oil-free model might be sufficient. Opt for an oil-lubricated compressor for professional use, heavy-duty projects, or if you require consistent high air pressure and flow.

The ideal air compressor size depends on two main factors: tank size and air delivery (CFM and PSI).

Refer to your air tool manuals for their specific PSI and CFM requirements. Our product pages often include air requirement charts to help you choose the right compressor for your needs.

An air compressor typically won't operate air tools directly. Here are some additional elements you might need:

Regular maintenance ensures your air compressor operates efficiently and lasts longer. Here are some basic maintenance tips:

While using an air compressor indoors occasionally might be alright with proper ventilation, it's generally not recommended. Here's why:

For indoor use, consider an oil-free air compressor with a noise reduction feature and ensure proper ventilation to remove moisture and exhaust fumes. Always prioritise safety and follow the manufacturer's recommendations for indoor use.

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Boost Your Productivity with the Toolair C_200-515: Engineered for High Performance in Transport, Workshops, and Agriculture. Toolair C_200-515 ...

View full details Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Experience Unmatched Efficiency and Durability with the Toolair C-270-850 Vertical Compressor, the Ultimate Choice for Professionals Demanding High...

View full details Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Transform Your Workshop with the Power and Precision of the Toolair C-270-850: The Ultimate Air Compressor for High-Demand Applications. Toolair...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Optimize Your Air Management with the SIP VSDD/RDF 15kW 8bar 500ltr Rotary Screw Compressor with Dryer & Filter (400V): Unmatched Performance a...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Experience Unmatched Efficiency and Reliability with the SIP VSDD/RDF 15kW 10bar 500ltr Rotary Screw Compressor with Dryer & Filter (400v): The...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Transform Your Air Supply with the SIP VSDD/RDF 11kW 8bar 500ltr Rotary Screw Compressor: Precision, Efficiency, and Reliability at the Heart of Yo...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Revolutionize Your Workflow with the SIP VSDD/RDF 11kW 10bar 500ltr Rotary Screw Compressor with Dryer & Filter: Where Innovation Meets Efficie...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Experience Unmatched Efficiency with theSIP RS7.5-10-270BDFF Rotary Screw Compressor: The Ultimate Solution for High-Quality Compressed Air SIP ...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Empower Your Operations with the SIP RS22-10-500BD/FF Rotary Screw Compressor: A Synthesis of Power, Precision, and Performance SIP RS22-10-500B...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Maximize Productivity with the SIP RS15-13-500BD/RD Rotary Screw Compressor: The Powerhouse of Efficiency and Performance for Industry Professional...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Enhance Your Air Power with the SIP RS15-10-500BD/RD Rotary Screw Compressor – A Masterpiece of Efficiency and Durability for Industrial Demands ...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Experience Unmatched Efficiency and Reliability with SIP RS15-10-500BD/FF Rotary Screw Compressor – Your Ultimate Solution for High-Quality Compres...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Elevate Your Industrial Capabilities with the SIP RS15-08-500BD/RD Screw Compressor: A Rotary Screw Compressor Designed for Efficiency and Durabili...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Optimize Your Air Solutions with the SIP RS11-10-500BD/RD Rotary Screw Compressor: A High-Performance Rotary Screw Compressor for Industrial Excell...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Streamline Your Operations with the SIP RS11-10-500BD/FF Rotary Screw Compressor: A High-Capacity Rotary Screw Compressor for Optimal Air Quality a...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in 'NaN' (Not a Number)%

Save Liquid error (snippets/product-badge line 32): Computation results in 'NaN' (Not a Number)%

Enhance Your Industrial Efficiency with theSIP RS11-10-270BD/FF Rotary Screw Compressor: The Ultimate Solution for Reliable and High-Quality Compre...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Maximize Efficiency and Minimize Noise with the SIP NB7.5/270 Silenced Compressor: Perfect for High-Demand Workshops Seeking Quiet Operation SIP...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Revolutionize Your Workshop with the SIP Rotary Screw RS15-10-500DD/RD: A High-Power, Low-Noise Rotary Screw Compressor with Advanced Technology fo...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Enhance Operational Efficiency with SIP Rotary Screw RS11-10-500DD/RD: The Ultimate Rotary Screw Compressor for Industrial Excellence SIP Rotary...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Optimize Your Operations with SIP Airmate TN7.5/270 Compressor (3phase)c/w Anti Vibs: The Ultimate Solution for High-Efficiency, Low-Maintenance Ai...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Optimize Your Workspace with SIP Airmate TN10/270 Compressor (3phase) c/w Anti Vibs: The 3-Phase Industrial Solution for Unparalleled Air Quality a...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

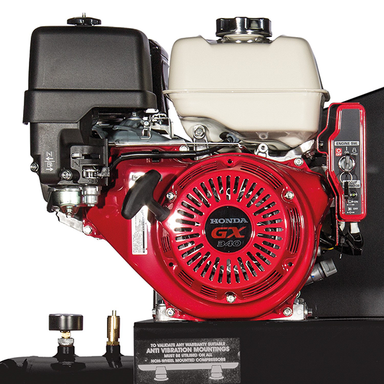

Revolutionize Your Air Power with SIP Airmate ISHP5.5/150 (Honda) Petrol Comp E/Start: Reliable, Efficient, and Ready for Any Challenge SIP Airm...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Elevate Your Industrial Capability with SIP Airmate ISHP11/200 (Honda) Petrol Compressor, a High-Capacity Powerhouse for Unrivaled Performance and ...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Experience Robust Power and Efficiency with the SIP Airmate ISHP11/200 (Honda) Petrol Comp E/Start – Engineered for High-Performance and Durability...

View full details