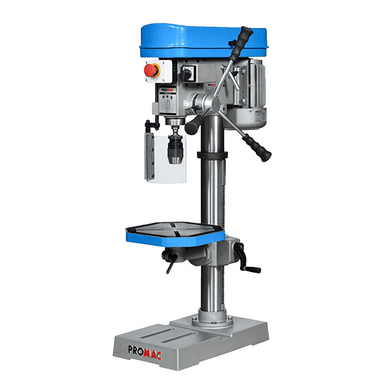

Promac 378VTE Bench Drill

Redefine Your Drilling Experience with the Promac 378VTE Bench Drill: Unmatched Precision and Versatility for Professionals and Hobbyists Promac...

View full detailsWelcome to the Drill Press Collection at Tool Bay Direct! Are you a seasoned professional, a passionate DIY enthusiast, or a budding woodworker seeking to elevate your project creations? Look no further than our curated selection of top-notch drill presses!

A drill press is a stationary power tool designed for precise drilling of holes in various materials like wood, metal, plastic, and even some composites. Unlike a handheld drill, which you maneuver freely, a drill press secures the workpiece in place. This allows for much greater control over the drill bit, resulting in:

Common Applications for Drill Presses

Overall, a drill press is a valuable tool for anyone who needs to drill precise and consistent holes. They offer greater control, accuracy, and efficiency compared to handheld drills, making them ideal for professional applications and serious DIY projects.

Precision Drilling

The defining feature of a drill press is its ability to drill holes with exceptional accuracy and control. Unlike handheld drills, the drill press secures the workpiece, allowing you to focus on precise positioning and depth control of the drill bit.

This translates to perfectly aligned and consistently sized holes, crucial for woodworking projects, doweling, and tasks requiring meticulous hole placement.

Variable Speed Control

Drill presses offer variable speed settings, allowing you to match the drilling requirements of different materials. Slower speeds work well for larger diameter holes, harder materials like metal, and preventing overheating of drill bits.

Conversely, higher speeds are ideal for smaller bits and softer materials like wood, achieving faster drilling and cleaner cuts.

Adjustable Spindle Travel

The spindle travel refers to the vertical distance the drill bit can move down from the chuck. This allows you to drill holes of various depths with precise control. Many drill presses offer depth stop features that allow you to set the exact drilling depth for repetitive tasks, ensuring uniformity throughout your project.

Sturdy Construction and Stability

Drill presses boast a robust design with a heavy base and a solid column. This stability minimizes vibrations and drill bit wobble, leading to cleaner, straighter holes. This is particularly important when drilling delicate materials or achieving precise hole alignments.

Versatility with Accessories (Some Models)

While the core function is drilling holes, some drill press models offer additional versatility with compatible attachments. These can include:

These features elevate the drill press beyond a simple drilling tool, making it a valuable asset for diverse woodworking and metalworking projects.

A drill press is an indispensable tool for achieving accurate and consistent holes in various materials. Unlike handheld drills, drill presses offer stability and control, making them ideal for tasks that require precision and repetition.

With features such as adjustable speeds, depth stops, and tilting tables, drill presses provide versatility and efficiency in your workshop.

Our Drill Press Collection caters to diverse needs and budgets. Here's a quick guide to help you select the right one:

Have questions or need assistance in choosing the right Drill Press for your needs? Our team of experts is here to help!

Phone:

Both drill presses and handheld drills create holes, but they offer different benefits. A handheld drill excels in portability and flexibility, allowing you to drill holes in various locations and at different angles. However, it requires more user control to achieve precise hole placement and depth.

A drill press, on the other hand, excels in precision and control. The secured workpiece and variable speed settings allow for highly accurate hole placement, consistent depths, and cleaner cuts. However, drill presses are stationary and less versatile for reaching tight spaces or drilling at odd angles.

Drill presses are generally user-friendly, with most models featuring intuitive controls. Learning basic techniques like setting the speed, adjusting the depth stop, and securing your workpiece doesn't require extensive experience. There are also plenty of beginner-friendly online resources and tutorials available to guide you.

Excessive vibration can be caused by several factors. First, ensure the drill bit is securely tightened in the chuck. Second, check if the workpiece is firmly clamped in the table or vise to minimize movement. Third, verify that you're using the correct speed setting for the material and drill bit size.

Using a dull or damaged drill bit can also contribute to vibration. Finally, some vibration might be inherent to certain models, particularly lighter-duty benchtop drill presses.

Safety first! Here are essential safety items for operating a drill press:

Broken drill bits can be caused by several factors. Ensure you're using the right type of drill bit for the material you're drilling. Overheating can also weaken and break drill bits, so make sure you're using the appropriate speed setting and not applying excessive force.

A dull or damaged bit is more likely to snap – inspect your bits regularly and replace them when necessary. Finally, double-check that the bit is securely tightened in the chuck to prevent slipping and potential breakage.

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Redefine Your Drilling Experience with the Promac 378VTE Bench Drill: Unmatched Precision and Versatility for Professionals and Hobbyists Promac...

View full details Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

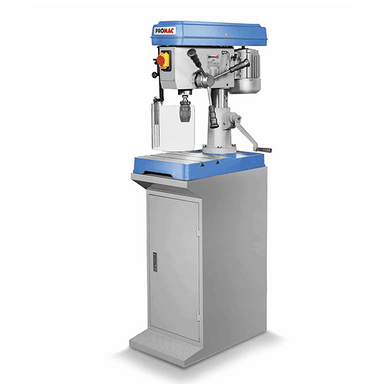

Experience Precision and Efficiency with the Promac 378CLB Benchtop Drill: Your Key to Advanced Metalworking Promac 378CLB Benchtop Drill Overvi...

View full details Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Enhance Your Workshop's Capabilities with the Promac 373E Benchtop Drill with Stand: Precision Engineering at Its Best Promac 373E Benchtop Dril...

View full details Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Enhance Your Workshop's Capabilities with the Promac 372E Benchtop Drill with Stand: Precision and Power at Your Fingertips Promac 372E Benchtop...

View full details Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Experience Next-Level Accuracy: The Promac 214AB-M Drill Press Delivers Unmatched Precision and Reliability for Your Workshop Projects Promac 21...

View full details Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Enhance Your Workshop Capabilities with the Promac 214AB Drill Press: Precision Drilling for Professional Results Promac 214AB Drill Press Overv...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Enhance Precision and Efficiency in Your Workshop with the Elmag RKBM 16T Radial V-Belt Table Drill – A Must-Have for Professionals and Educators A...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Maximize Your Productivity with the Elmag Radial Column Drill RSBM 4 32 ECO - The Ultimate Solution for Precision and Power in Industrial Drilling ...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Enhance Your Drilling Capability with Elmag PREMIUM High-Speed Column Drill R32VS PGM: Precision Meets Versatility Elmag PREMIUM High-Speed Colu...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Revolutionize Your Workshop with Elmag PREMIUM High-Speed Column Drill F28 PGM: The Ultimate in Precision and Flexibility Elmag PREMIUM High-Spe...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Maximize Efficiency with Elmag PREMIUM High-Speed Column Drill R40E PGM: The Powerhouse for Advanced Drilling Precision Elmag PREMIUM High-Speed...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Elevate Your Drilling Standards with the Elmag KBM 32 S I-Vario V-Belt Column Drill – Precision Meets Power Elmag KBM 32 S I-Vario V-Belt Column...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Master Precision and Performance with the Elmag KBM 32 S I-Vario Set – The Ultimate Tool for High-Quality, Detailed Drilling Elmag KBM 32 S I-Va...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Transform Precision Drilling with the Elmag KBM 25 S I-Vario V-Belt Column Drill Elmag KBM 25 S I-Vario V-Belt Column Drill Overview Discover t...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

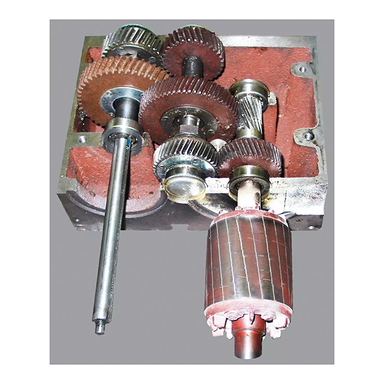

Elmag Gear Milling and Drilling Machine MFB 20-L Vario: Precision Milling and Drilling at Your Fingertips Elmag Gear Milling and Drilling Machin...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Enhance Your Machining Capabilities with Elmag Gear Milling and Drilling Machine MFB30 Vario: Precision and Flexibility in Every Turn Elmag Gear...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Experience Unmatched Drilling Precision and Versatility with the Elmag Gear Column Drill GBM 4/35 SGA Set — Ideal for High-Demand Metalworking! ...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Unleash Robust Drilling Power with Elmag Gear Column Drill GBM 3/30 SNA: Engineered for Excellence Elmag Gear Column Drill GBM 3/30 SNA Overview...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Master Precision Drilling with Elmag Gear Column Drill GBM 3/25 SNE Set: A Complete Solution for High-Performance Machining Elmag Gear Column Dr...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Discover the Elmag GBM 4/35 SGA Gear Column Drill: A Precision Powerhouse for All Your Drilling Needs! Equipped with smooth-running gears and thr...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Elevate Your Drilling Projects with Elmag GBM 3/30 SNA Gear Column Drill Set: Precision, Power, and Versatility All-in-One Elmag GBM 3/30 SNA Ge...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Elmag GBM 3/25 TNE Gear Bench Drill Set: The Ultimate Drilling Powerhouse for Precision and Versatility Elmag GBM 3/25 TNE Gear Bench Drill Set ...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Elmag GBM 3/25 TNE Gear Bench Drill: Engineered for Excellence in High-Speed Precision Drilling Elmag GBM 3/25 TNE Gear Bench Drill Overview Th...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Transform Your Workshop with Elmag GBM 3/25 SNE Gear Column Drill: A Symphony of Power and Precision Elmag GBM 3/25 SNE Gear Column Drill Overvi...

View full details