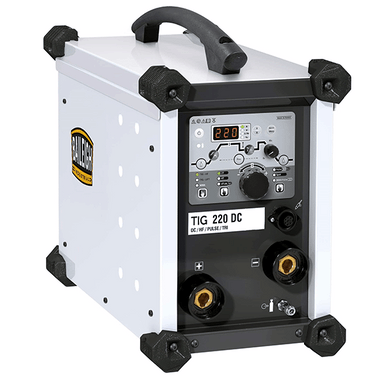

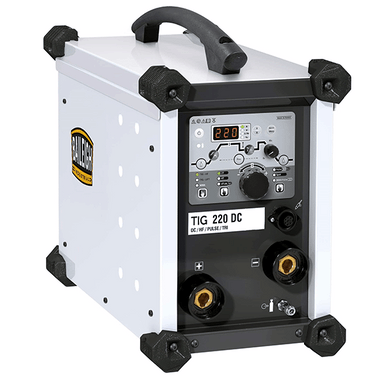

Baileigh BW-220T-220A TIG Welder 220amp

Unlock Unmatched Welding Performance with the Baileigh BW-220T-220A TIG Welder: The Professional's Choice for Precision and Quality Baileigh BW-...

View full detailsWelcome to the TIG Welders Collection at Tool Bay Direct! Are you a professional welder seeking the ultimate in weld quality, or a passionate DIY enthusiast looking to tackle intricate metal projects? Look no further than our curated selection of top-notch TIG welders (also known as GTAW - Gas Tungsten Arc Welding). TIG welding offers unmatched precision and control, making it ideal for:

TIG welding utilizes a non-consumable tungsten electrode and an inert gas shield to protect the weld pool from contamination. Unlike MIG welding, the filler metal is typically a separate rod, allowing for precise control over the amount of metal deposited. This technique demands more skill than other methods, but rewards the user with exceptional weld results.

Unmatched Precision and Control

TIG welding offers the ultimate in control for creating high-quality welds. The non-consumable tungsten electrode and separate filler rod allow for meticulous placement of filler metal, resulting in clean and precise welds on thin sheet metal, intricate repairs, and even achieving flawless visual aesthetics on exposed welds.

Versatility Across Various Metals

TIG welders excel at joining a wide range of metals, making them highly versatile for diverse projects. From common ferrous metals like steel and stainless steel to reactive metals like aluminium, titanium, and even nickel alloys, TIG welding can handle it all with the appropriate settings, tungsten electrode type, and filler rod selection.

Clean Welds on Thin Materials

Unlike some arc welding processes, TIG welding minimizes heat input due to the non-consumable electrode. This characteristic makes TIG ideal for welding thin sheet metal without the risk of burn-through or warping. The precise control over filler metal deposition further aids in creating clean and strong welds on delicate materials.

AC/DC Current Capability (Advanced TIG Welders)

While beginner-friendly TIG welders often operate on DC current (ideal for steel and stainless steel), advanced TIG welders offer AC/DC current. AC current allows for welding aluminium and other reactive metals by rapidly breaking down the oxide layer that typically hinders a stable weld.

Foot Pedal Control (for Increased Precision)

TIG welders often feature a foot pedal for variable amperage control. This frees up your hands for torch manipulation and allows for real-time adjustments to the weld pool size and penetration as you weld. This degree of control over heat input is particularly beneficial for achieving optimal results on various materials and thicknesses.

TIG welding stands out for its ability to produce high-quality welds with exceptional accuracy. By using a non-consumable tungsten electrode and inert gas shielding, TIG welding ensures clean and precise welds, making it ideal for projects that demand utmost precision and aesthetic appeal.

From automotive repairs to intricate metalwork, TIG welding offers unmatched control and finesse.

Our TIG Welders Collection caters to various skill levels and project needs. Here's a quick guide to help you choose the right one:

Have questions or need assistance in choosing the right TIG Welder for your needs? Our team of experts is here to help!

Phone:

TIG welding does require more skill and practice compared to other techniques like MIG welding. The focus on maintaining a stable arc, hand-feeding filler metal, and controlling the foot pedal can be initially challenging. However, with dedication and practice, beginners can achieve good results.

There are many online resources and beginner guides available to help you get started.

The main difference lies in the electrode. MIG torches use a continuously fed consumable electrode wire, while TIG torches utilize a non-consumable tungsten electrode. Additionally, TIG torches have a separate gas lens to direct the shielding gas around the tungsten electrode and weld pool, whereas MIG torches rely on the consumable electrode to channel the gas.

Yes, but you'll need an advanced TIG welder with AC/DC current capability. Standard TIG welders operate on DC current, unsuitable for welding aluminium due to its oxide layer. AC current rapidly breaks down this oxide layer, allowing for a stable weld. Additionally, you'll need specific aluminium filler rods and may require adjustments to your TIG welder settings for optimal results.

Black discoloration on your welds often indicates contamination from the tungsten electrode or surrounding area. Ensure the tungsten electrode is clean and free of contamination before welding. Also, check if the metal surface is clean and free of grease, paint, or rust. These contaminants can interfere with a clean weld and cause discoloration.

Safety first! Here are essential safety items for TIG welding:

Remember to always follow safe welding practices and refer to your TIG welder's manual for specific instructions.

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Unlock Unmatched Welding Performance with the Baileigh BW-220T-220A TIG Welder: The Professional's Choice for Precision and Quality Baileigh BW-...

View full details Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Achieve Precision in Every Weld with the Baileigh BW-200T-200A TIG Welder: The Go-To AC/DC Solution for Reliable Welding Projects Baileigh BW-20...

View full details Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Transform Your Welding Projects with the Baileigh BW-168T-160A TIG Welder: Precision, Versatility, and Quality for a Range of Metals Baileigh BW...

View full details