Pro Spot MIG/MAG Mobile Welding Inverter

Revolutionize Your Welding with Pro Spot MIG/MAG Mobile Welding Inverter The Ultimate MIG/MAG Inverter for Seamless Multi-Material Welding in Profe...

View full detailsHere at Tool Bay Direct, we pride ourselves on providing top-quality welding equipment to our valued customers. Whether you're a seasoned professional or a hobbyist looking to tackle new projects, our range of MIG welders offers versatility, reliability, and performance. Let's dive into the world of MIG welding and explore our extensive collection of MIG welders.

1. Weld Like a Pro: Explore the Top MIG Welders

2. Key Features of MIG Welding

3. Why Choose MIG Welding?

4. Choosing the Right MIG Welder for Your Needs

5. Expert Advice and Support

6. FAQs about MIG Welders

MIG welding, also known as Gas Metal Arc Welding (GMAW), is a popular and versatile arc welding process that utilizes a continuously fed consumable wire electrode. The electrode melts, forming the weld pool, while a shielding gas protects the molten metal from contamination.

Clean and Precise Welds

MIG welding produces smooth, spatter-free welds with excellent control. The continuously fed wire electrode and inert gas shielding minimize oxidation and spatter, resulting in clean and visually appealing welds. This is particularly beneficial for projects where aesthetics are important.

Versatility Across Metals

MIG welders are renowned for their ability to handle a wide range of metals. From common mild steel and stainless steel to aluminium and even thin sheet metal, MIG welders can adapt to various projects with the appropriate wire and gas selection. This versatility makes MIG a favourite for workshops and fabrication shops dealing with diverse materials.

Faster Welding Speeds

Compared to other arc welding techniques, MIG welding offers significantly faster completion times. The continuous wire feed eliminates the need for frequent electrode changes, allowing for uninterrupted welding and increased productivity. This efficiency is especially advantageous for larger projects or production environments.

User-Friendly Operation

MIG welders are known for their ease of use, making them ideal for both beginners and experienced welders. Unlike some trickier techniques, MIG welding often features intuitive controls and semi-automatic wire feed, allowing users to focus on torch manipulation and weld puddle control. This user-friendliness lowers the barrier to entry for new welders.

Adjustable Power and Control

Despite their user-friendly nature, MIG welders offer a surprising degree of adjustability. Settings like wire feed speed and voltage allow for fine-tuning the weld pool characteristics to suit the material thickness and desired penetration. Advanced MIG welders may even offer features like pulse settings for delicate sheet metal or synergic control for a truly automated welding experience.

MIG welding offers several advantages over other welding processes. It provides high welding speeds, excellent control over the weld pool, and minimal post-weld cleanup. Additionally, MIG welding can be easily automated, making it ideal for high-volume production environments.

Whether you're working on automotive repairs, fabrication projects, or DIY home improvements, MIG welding provides the versatility and performance you need.

Whether you're a beginner looking to start welding as a hobby or a professional welder seeking a reliable machine for industrial use, several factors should influence your decision. Here's a comprehensive guide to help you choose the perfect MIG welder for your needs:

Have questions or need assistance in choosing the right product for your needs? Our team of experts is here to help!

Phone:

Email: info@toolbaydirect.co.uk

Absolutely! MIG welding is known for being user-friendly compared to other techniques. Look for a beginner-friendly MIG welder with clear controls and possibly an auto-set feature for basic materials like mild steel. There are also plenty of online resources and beginner guides to help you get started.

Excessive spatter can be caused by several factors. Check if the wire feed speed is set too high, causing the electrode to burn back into the contact tip. Worn-out or dirty contact tips can also contribute to spatter. Ensure you're using the correct wire diameter and type for the material you're welding.

Finally, improper welding techniques, particularly torch angle and travel speed, can lead to spatter.

Yes, but it requires a spool gun attachment specifically designed for aluminium welding. Standard MIG torches aren't suitable for aluminium due to its reactivity with air. The spool gun isolates the wire from the atmosphere and feeds it directly to the weld pool.

Additionally, you'll need specific aluminium welding wire and adjustments to your MIG welder settings for optimal results.

Porosity refers to tiny air bubbles trapped within the weld. It can be caused by several factors, including:

Safety is paramount! Here are essential safety items for MIG welding:

Remember to always follow safe welding practices and refer to your MIG welder's manual for specific instructions.

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Revolutionize Your Welding with Pro Spot MIG/MAG Mobile Welding Inverter The Ultimate MIG/MAG Inverter for Seamless Multi-Material Welding in Profe...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Elevate Your Welding Artistry with Elmag's PROFI-MIG 3000 Plus MIG 304 - The Quintessence of Precision and Power in Shielding Gas Welding Technolog...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

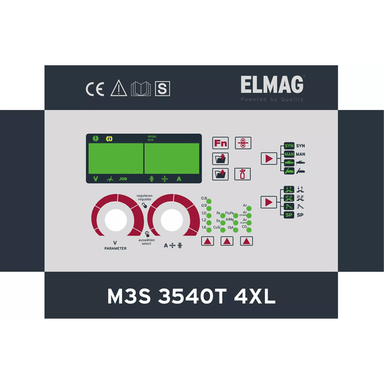

Experience Unparalleled Versatility and Efficiency with the Elmag Multifunctional Welding Inverter M3S 3540T 4XL / ECO-SET - Your Comprehensive Sol...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Transform Your Welding Experience with the Elmag Multifunction Portable Welding Inverter Steel Set (ETP220 SynPuls), the Compact Powerhouse for Pro...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Maximize Your Welding Capabilities with the Elmag Multifunction Mobile Welding Inverter Steel Set (ETP225 SynPuls), the Ultimate Tool for High-Prec...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Enhance Your Welding Flexibility with the Elmag Multifunction Mobile Welding Inverter Steel Aluminium Set (ETP225 SynPuls), a Robust Solution for H...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Experience Versatile Welding Excellence with the Elmag Multifunction Mobile Welding Inverter Set (ETP225 SynPuls), Engineered to Deliver Precision ...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Master Every Weld with Elmag Multifunction Mobile Welding Inverter Set (ETP 220 SynPuls): The Versatile Inverter for Premium MIG, TIG, and MMA Weld...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Streamline Your Welding Projects with the Elmag Multifunction Mobile Welding Inverter Basic Set (ETP220 SynPuls), Your Go-To Solution for Efficient...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Experience Unmatched Flexibility with Cebora MIG/MAG Continuously Adjustable Welding System: Your Solution for Precision MIG/MAG Welding Across a R...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Master the Art of Welding with Elmag Multifunction Welding Inverter Steel Aluminum Set (ETP220 SynPuls): The All-in-One Solution for MIG/MAG, TIG D...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Revolutionize Your Welding with Cebora Impact Multifunction Welding System (SYNSTAR 330 TS): The Future of Multi-Process Welding Technology, Tailor...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Master Every Weld with Cebora Impact Multifunction Welding System (SYNSTAR 330 TC): The Powerhouse of Precision, Versatility, and Efficiency in a C...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

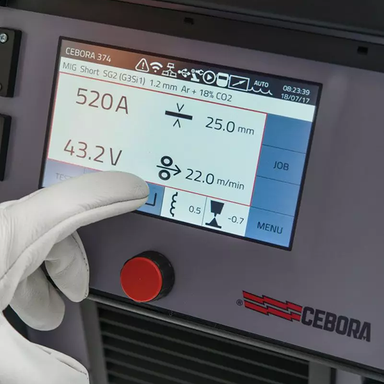

Revolutionize Your Welding with Cebora Impact Multifunction System KING STAR 520 TS: The Ultimate Tool for Advanced Welding Technology Cebora Im...

View full details Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Enhance Your Welding Artistry with the Baileigh BW-160MT-160A MIG/MAG Welder, the Perfect Fusion of Portability and Precision for Every Metalwork M...

View full details Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Elevate Your Welding Game with the SIP HGT4000S SWF MIG Transformer Welder: Unmatched Precision for Professional Results SIP HGT4000S SWF MIG Tr...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Experience Welding Mastery with the SIP HG4500 MIG/ARC Synergic Inverter Welder: A Powerhouse for Professional Applications SIP HG4500 MIG/ARC S...

View full details

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Save Liquid error (snippets/product-badge line 32): Computation results in '-Infinity'%

Enhance Your Welding Projects with the Elmag Shielding Gas Welding System PROFI-MIG 3000 Plus / MIG 274 - The Ultimate Tool for Precision, Versatil...

View full details